Quality and reliability guaranteed.

Applications involving continuous movement require special cables with advanced mechanical resistance qualities. In automated applications, such movement rapidly deteriorates conventional cabling.

The problem lies in the fact that most cables are not designed for this type of motion (bending and pulling) and wear quickly. Repeated bending in copper conductors causes them to “ecold harden” and “break”. Cold copper conductor wires are stretched beyond the limits of their elasticity. When a conductor is flexed (bent) over a radius that is too small, it becomes overstretched. This action alters the internal structure of the conductor causing it to become brittle, and therefore liable to breakage.

Similarly, the friction created by the internal elements of a cable in motion can generate enough heat to cause the cable insulation, shielding and/or sheath to fail. By internal elements we are referring to the different layers and parts in a cable, such as conductors, insulation, shields, protection tapes, outer sheath, etc.

Process automation machines are designed to operate at higher speeds than previous generations and are equipped with increasingly complex vision and control systems as well as a wide variety of sensors.

This new operational scenario demands more resistant and reliable cables. At Sumcab, we have created cables that are compliant with the most stringent requirements for mechanical resistance, chemical aggression and thermal range. Designed to support millions of bending cycles, always with very small bend radii (down to 5 x d). They are also very resistant to many additional environmental factors, such as changeable temperatures, oils/greases and chemical products.

The reliability of our products is ensured at our own technical laboratory equipped with 3D testing system. This system allows cables to be tested under conditions of rapid acceleration and deceleration, traction forces, compression and continuous bending and twisting.

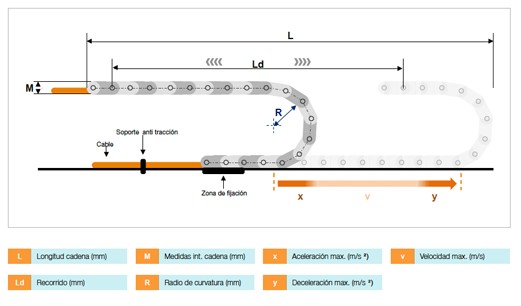

What is a cable chain?

Metal or plastic cable chains are mechanical systems designed to protect and guide moving machinery’s cables and hoses. There are different models, taking into account length, track, speed of the moving piece, space, cables to transport, environment, etc.

Applications:

Machine tool – Automotive – Machining centers – Maintenance – Packaging – Automated assembly lines – Robotics – Telescopic arms – Cranes – Self-car washing

Example of cable chain design

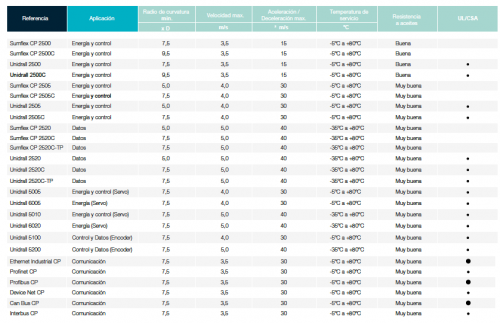

Choosing the right cable

The cables for cable chains feed and/or control moving machines which makes guaranteeing the perfect operation of the system paramount (power transmission, control, data, and communication). During the cable’s service life it will be subject to millions of movements in very small spaces, rubbing, very high movement speeds as well as constant acceleration and deceleration. Other factors like bend radius, severe industrial environments, service temperatures, and contact with aggressive chemical products will also affect the chain’s lifespan

Considerations:

- Application (power, control, data, communication)

- Type of chain (metal or plastic)

- Chain’s interior measurements

- Chain’s length

- Movement speed

- Acceleration/deceleration

- Bend radius

- Environment (temperature, contact with chemical products)

- Regulations

The most advanced solution for industrial automation

Using the right cable impacts directly on automation equipment reliability. Understanding the causes of cable failure in applications of this nature enables us to take the appropriate measures during the design phase to increase the reliability of our clients’ entire production systems.

Sumcab range of solutions

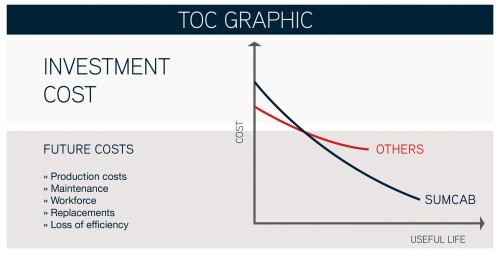

TOC Graph

Sumcab’s cables decrease the costs throughout the entire useful life of the machines and equipment because they are tailored to the customer’s needs and the application demands. This increase noticeably the operation time and minimises the expected and unexpected stop times. Along with all the benefits regarding products, the customer also benefits from lower planning costs expenses and installation costs, thanks to our adapted solutions.