Independent manufacturers

In a world in which the bigger market players set the rules, often the only solution is to adapt to the rules they impose. However, being listened to, demanding without conditions the solution that really suits us best, is the only path to excellence. The surrounding environment is increasingly demanding and competitive. Having one single option, that often doesn't fully meet our needs, is not enough. The best is that which is built together, which really makes the difference and will be the competitive key in the future. Sumcab builds cable solutions, peripherals for robots and security systems for automated areas. And what is even more important, Sumcab builds relationships between people, so that you can be the one who leads the way.

Premises

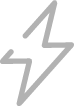

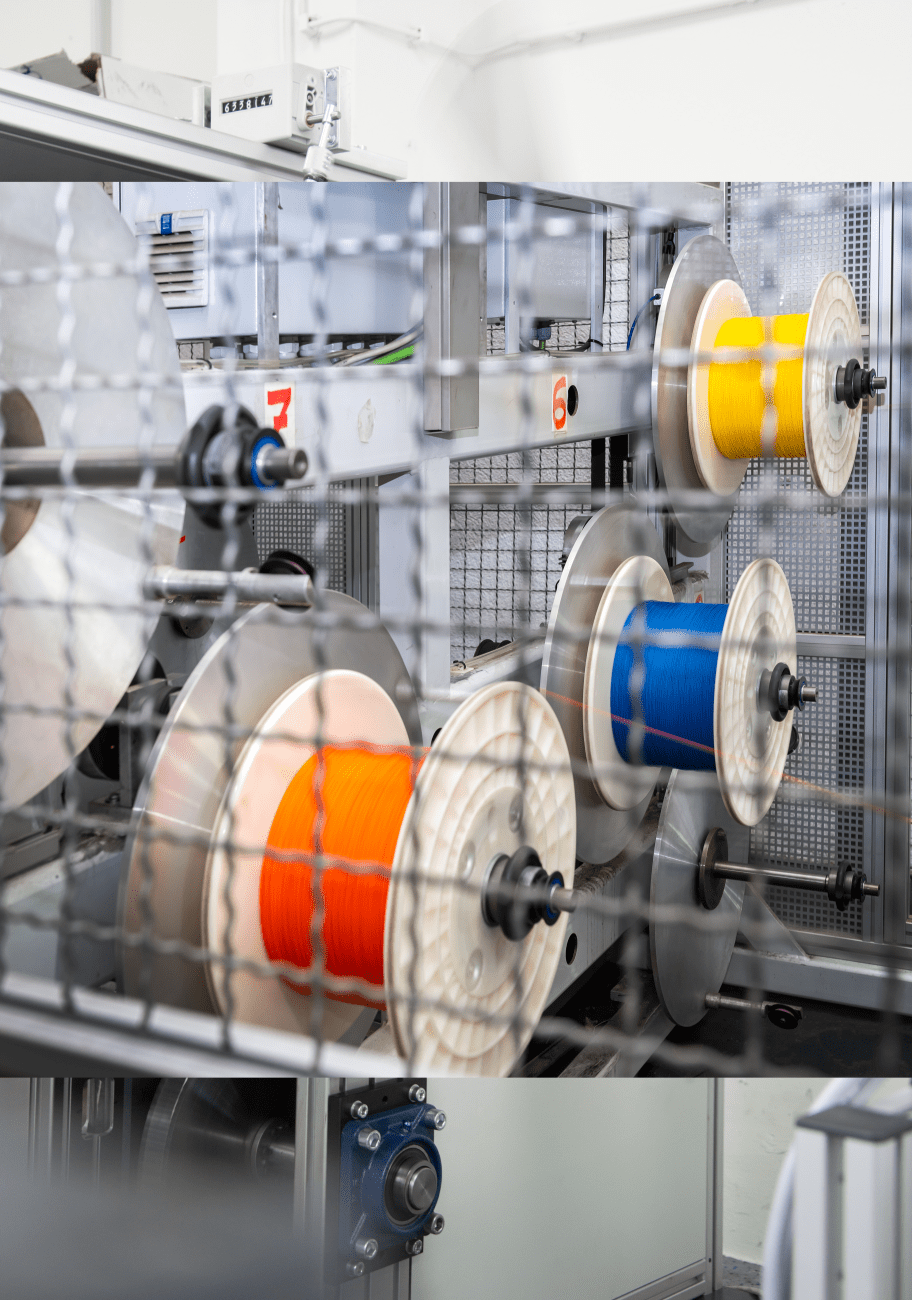

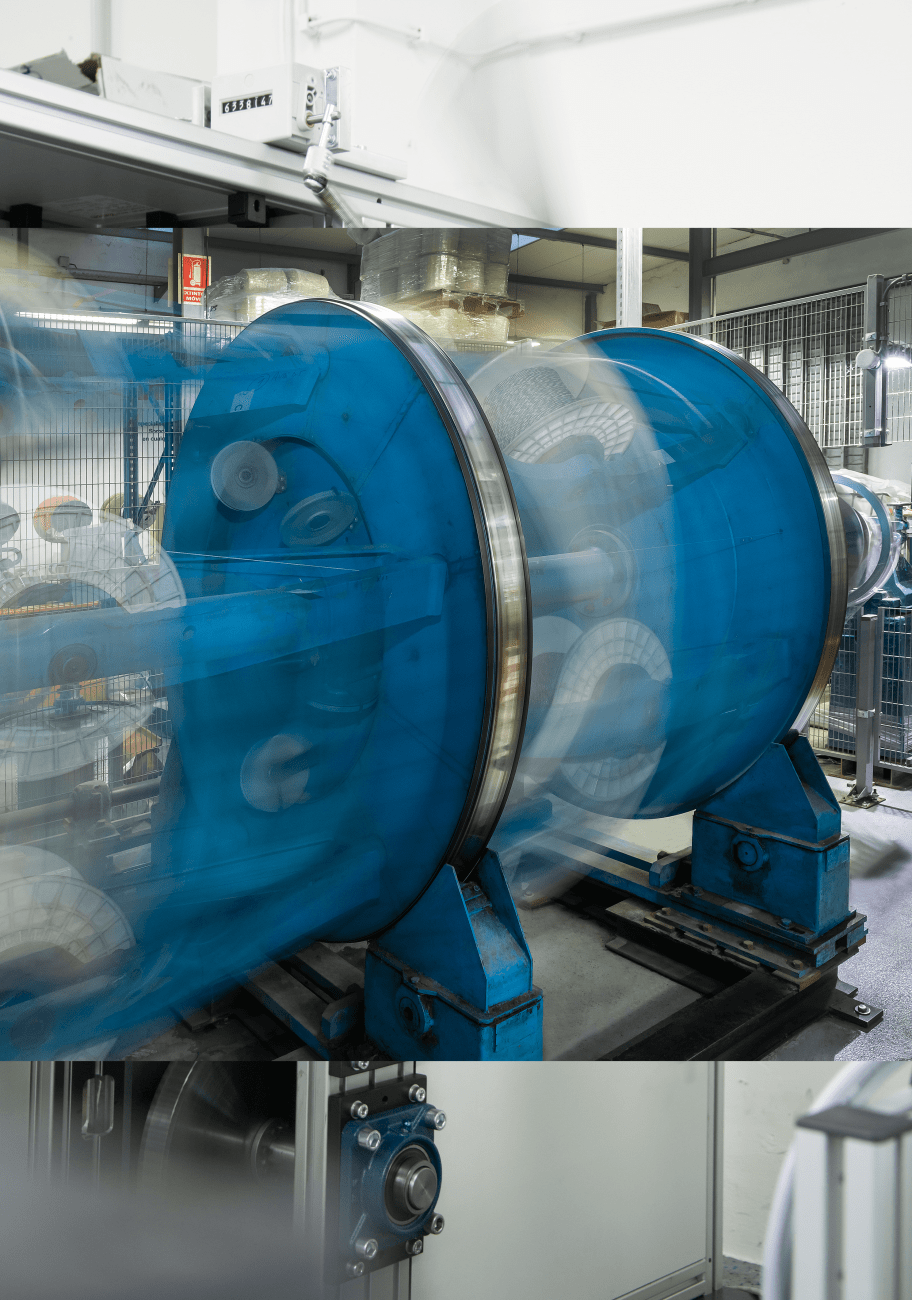

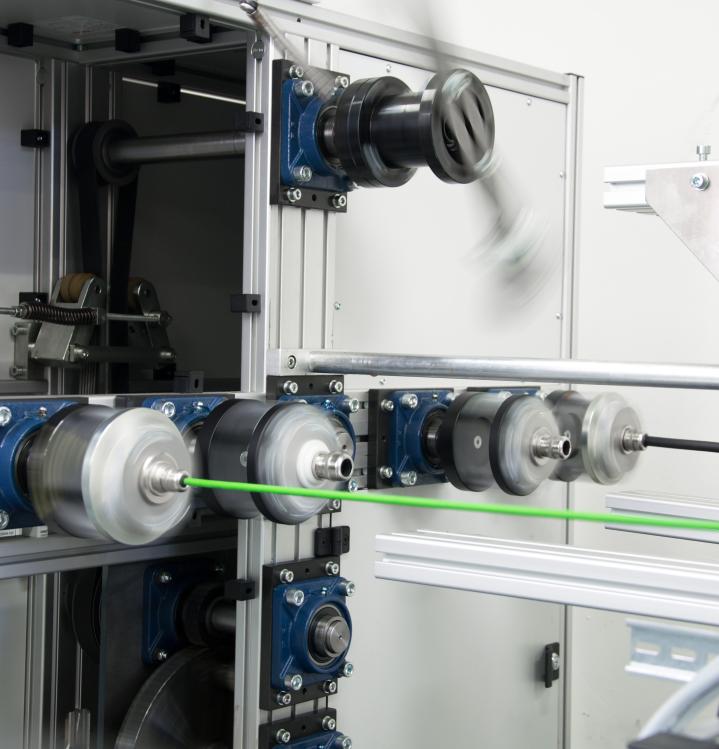

Sumcab's centre is equipped with the best infrastructure for developing projects with high added value. The cables are manufactured according to the customer's requirements and the application requirement. Research and development is one of the pillars on which Sumcab's growth is based.

Sumcab's technological innovation guarantees the development of new materials, manufacturing processes and products, providing essential differential value in the market.

Applications

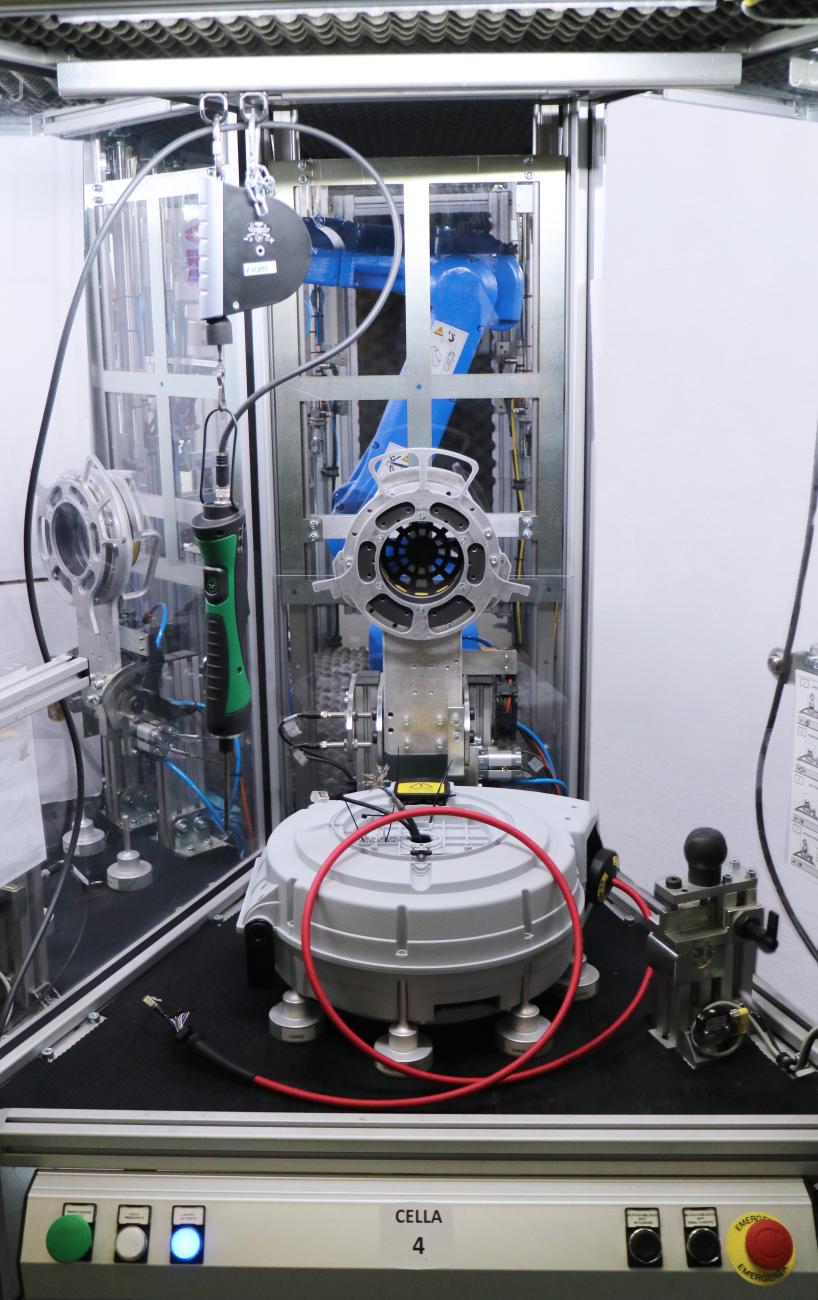

- Industrial Automation

- Robotics

- Remotely Operated Vehicles

- Subsea & Underwater Technology

- Rolling Stock

- Nuclear & Scientific