Special cables for high frequency Welding

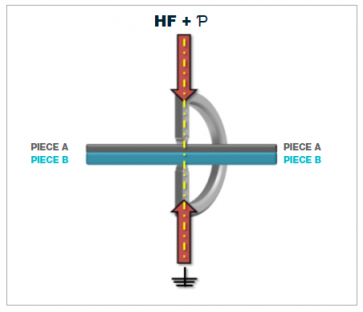

High frequency welding serves to join two pieces (A+B) by supplying high frequency (HF) energy in the form of an electromagnetic field and pressure through compression (?). The energy is generated by a generator, the power is supplied by an electrode. The electric energy generates movement of the molecules of the material and thus generates heat. This process, along with the constant compression pressures, melts both pieces. Unlike conventional welding, the heat is created inside the pieces themselves and does not come form an external source. When the material cools down, a higher quality welding point has been created. This results in a highly resistant and effective welding.

The primary benefit of this method is the fact that it is a constant process. In other words, it can be applied to larger surfaces without having to interrupt and/or remove the welding clamp, which increases productivity significantly. The process is usually clean and very accurate as just the joining area/point will be heated.

Sumflex Mechatronic HFS

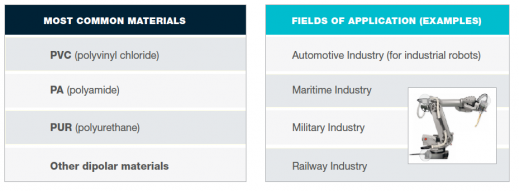

Special made-to-measure cables are required due to the Skin Effect* generated at 10 KHz frequencies. Sumcab Tailor Made Cables has developed Sumflex Mechatronic HFS for high frequency use. This cable has been created to transmit energy efficiently. Its design serves to optimise the current density distribution of the conductor. The cable consists of several groups of bare copper, extra-flexible threaded conductors. Each group is insulated by a special tape

Moreover, our cable Sumflex Mechatronic HFS complies with the most demanding requirements regarding mechanical resistance, chemical aggressiveness and thermal amplitude. Designed to support millions of bending, twisting and pulling cycles, always with very small curve radii (down to 5 x d). They are also very resistant to many additional environmental factors, such as changeable temperatures, oils/greases and chemical products.

Skin-Effect

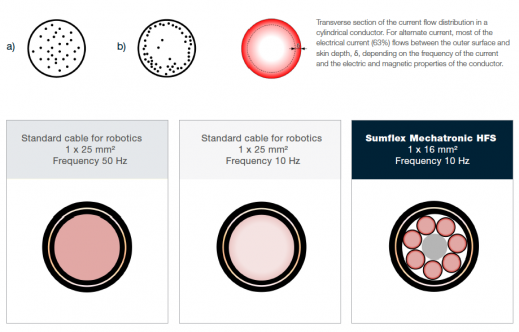

In direct current, the current density is similar along the entire conductor (figure a), but in alternate current it can be observed that the current density is higher on the surface than on the centre (figure b). This phenomenon is known as Skin effect or Kelvin effect. This phenomenon causes the effective or alternate current resistance to be higher than the ohmic or high current resistance. This effect causes the variation in electric resistance in the alternate current of a conductor due to the variable frequency of the electric current that travels across it.