Drag Chain SUMODRIVE cables feed and / or control mobile machines and therefore it is of crucial importance to ensure a perfect operation of the system (energy transport, control, data and communication).

During a cable’s lifetime, it will be subjected to millions of movements in very small spaces, friction, very high travel speeds, as well as constant accelerations and decelerations. Other factors such as bending radius, severe industrial environments, service temperature and contacts with aggressive chemicals will also affect the longevity of the cable.

In order to meet these needs, Sumcab offers a complete range portfolio of special cables for drag chains.

Guaranteed Reliability & Quality

We develop and manufacture special cables, capable of meeting the most demanding requirements in terms of mechanical strength, aggression and thermal amplitude.

Cables for use in automated machinery, drag chains or industrial robots. The cables must withstand millions of flex cycles, always with very small bending radius (5 x D). In addition, they must resist a wide variety of additional environmental effects, such as variable temperatures, oils/fats and/ r chemicals.

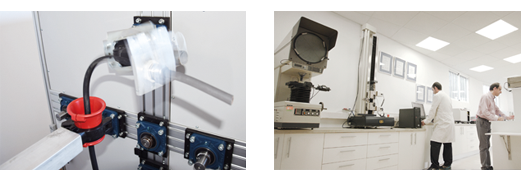

In order to meet these requirements, our cables for movement, are tested in our own laboratory with a custom test system. This self-developed system checks the cables with fast accelerations, tensile stresses and continuous flexes for millions of cycles.

The correct choice of cable

What aspects should be taken into account when choosing the right cable?

- Application

- Type of chain

- Internal measurements of the chain

- Length of the chain

- Travel speed

- Acceleration/Deceleration

- Bending Radius

- Work environment (temperature, external agents, etc.)

- Horizontal or Vertical installation

- Requested standards and/or regulations

European companies, leaders in the automotive sector, already rely on our products, providing them the necessary approvals for its use in their production plants.

Do not hesitate to contact us!

- UL & CSA Certified

- Manufactured in Spain

- Designed to withstand up to 10 Mio of bending movements (depending on the application)

- Extremely small bend radius

- Wide range in stock

- Made to measure cuts

- 24h delivery nationwide

- Custom technical support