For more demanding industrial settings.

The use of instrumentation cables for the transmission of analogue and digital signals is increasing. Protection against external influences is highly important in order to preserve the information transmitted.

In terms of industrial environments, these external influences can be particularly disruptive. There are numerous possible threats and they are more prevalent than in residential environments.

In this type of environment, it is possible to outline different types of aggressions such as chemical attacks, the possibility of fires, the penetration of moisture and water and electromagnetic interference (EMI).

Aggressions produced by chemical agents have an adverse effect on the cable’s materials, resulting in the deterioration and corrosion of the cable’s cover and subsequently of the insulation of the conductors, reducing or even stopping signal transmission.

These products, such as oils, hydrocarbons, solvents, acids, salts, bases and aggressive gases lead to a reduction of mechanical resistance, fragility or softening of materials and increased permeability.

In uses where the cables may be subject to attacks such as those mentioned, the external cable covering is insufficient, and therefore it is is necessary to use additional protection. The traditional solution for such cases was a lead cover.

Lead pollution is a matter of world importance. This substance is not only harmful for the environment, it also harms the health of people. Lead is one of the substances referred to in the European Union (EU) directive concerning the Restriction of hazardous substances in electrical and electronic equipment (RoHS). It is also a banned substance in many countries across the world.

SUMCAB has developed a new type of protection, for cables to be used for industrial applications, as an alternative to traditional constructions with lead covers. Sumcab’s S-BLOCK barrier performs in a very similar way to lead but offers several advantages:

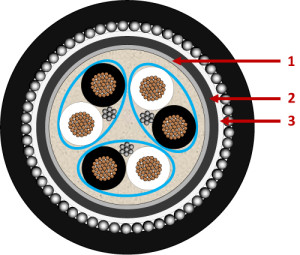

- The main characteristic of this protection is its composition in three layers formed by plastics and strips of metal used as barriers against chemical agents and moisture. Each layer has its own role as shall be explained later in greater detail.

- The purpose of creating this alternative was to come as close as possible to recreating the good properties that lead has such as impermeability and good resistance against chemical attacks while offering different improvements that make this solution more appealing.

SUMCAB TAILOR MADE CABLE (STMC), the new Sumcab group production centre aimed at the production of special cables, is responsible for the development of this new product.

S-Block is especially characterised by its additional layer of polyamide on a covering layer of high-density polyethylene (HDPE) thereby managing to create a magnificent solution for Oil & Gas uses. The three layers that form this barrier are:

- - Strip of copolymer/aluminium: impermeable against moisture and excellent protection against electromagnetic interference.

- - High-density polyethylene (HDPE): resistant to inorganic chemical products.

- - Polyamide: resistant to organic chemical products.

- The copolymer/aluminium strip placed directly on the cable set of the conductors, is comprised of an aluminium strip covered in a layer of copolymer that is firmly stuck down, forming an airtight tube. During the extrusion of the high-density polyethylene, the copolymer is firmly attached to the polyethylene forming a watertight cover. Also, the aluminium acts as a screen providing protection against EMI. The polyamide cover is the last layer of this multiple barrier.

- In its point concerning chemical and environmental protection, the European regulation for instrumentation and control cables (EN 50288-7) now includes this multilayer option as an alternative to lead covering. By doing this, it is hoped that cable manufacturers will use this solution that has several advantages compared to the traditional version.

The use of the copolymer/aluminium strip, of the HDPE cover and of the polyamide instead of the lead cover, makes it possible to reduce the size of the cable’s final diameter and this in turn makes the cable more effective for use in piping, when using smaller accessories, and in a smaller bend curvature. - A cable with this protection weighs less, it is easier to handle and makes it possible to use support for lighter construction.

The cost of the cable is considerably cheaper in comparison to a cable with a lead cover. This also applies to the installation costs given that it is easier to handle, as well as to the transport costs due to a reduction in weight and the final diameter of the cable.

The cable is available in its armoured version and unarmoured version with a fireproof cover. The cable is available in various different construction formats on request, such as halogen-free or fire resistant.

S-block is presented as a comprehensive solution, a product that more than meets the most specialist needs of the Oil & Gas market. It is a unique solution against multiple external aggressions resulting from the most demanding industrial environments.