The cables for cable chain feed and/or control mobile machines and therefore it is of crucial importance to ensure the perfect operation of the system (energy transport, control, data and communication).

During a cable’s lifetime, it will be subjected to millions of movements in very small spaces, friction, very high travel speeds, as well as constant accelerations and decelerations.

Other factors such as the curvature radius, severe industrial environments, service temperature and contacts with aggressive chemicals also affect the longevity of the cable.

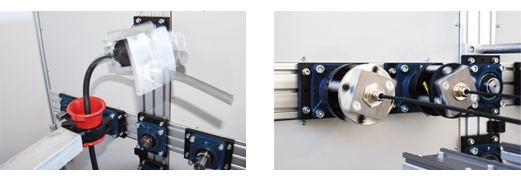

In order to meet these requirements, the cables for movement must be tested in a laboratory with a custom test system. This system checks the cables with fast accelerations, tensile stresses and continuous flexes for millions of cycles.

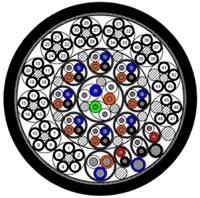

The cable design

- Extra flexible and concentrically formed copper wires

- Insulation and cover with high mechanical resistance

- Torque free wiring

- Short wiring sections

- Fillers and anti-friction weatherstripping

- Suitable design for homogenizing the mechanical stress on the cable assembly

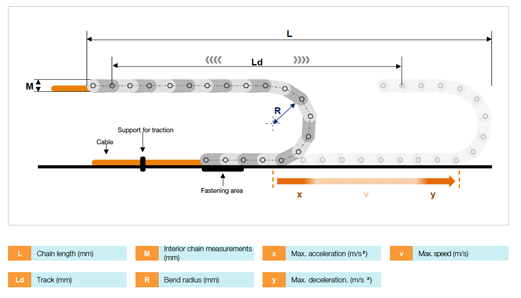

What aspects should be taken into account when choosing the right cable?

- Application (power, control, data, communication, etc.)

- Type of chain (metal or plastic)

- Internal measurements of the chain

- Length of the chain

- Travel speed

- Acceleration/deceleration

- Radius of curvature

- Work environment (temperature, external agents, etc.)

- Horizontal or vertical installation

SUMCAB Specialcable Group

Expect High Performance