Description and application

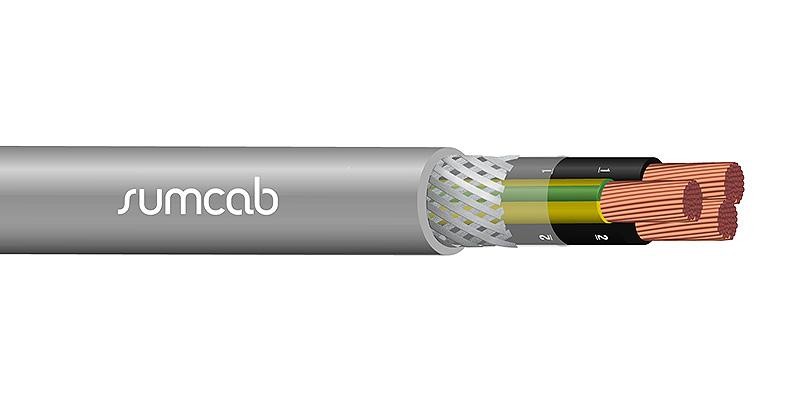

Flexible power and control cable with copper braid shield, PVC 600 V, with North American certification TC-ER (Tray Cable Exposed Run) for laying without protection in cable trays. Electromagnetic interference (EMI) protection.

-

Featured benefitsFlexible,Protección electromagnética,Certified in the US & Canada for tray installation

-

LocationIndoors/Outdoors

-

Type of installationFixed

Design

-

Overall cable shieldTinned copper braid, coverage of min. 80%

- ConductorBare copper wires, flexible, Class 5 to IEC 60228

- InsulationThermoplastic compound

- IdentificationNumbered black with/without yellow/green

- SheathSpecial PVC

- ColourGrey

Technical characteristics

-

Service temperature in fixed and protected installation-40 °C to +90 °C

-

Service voltage600 V

- Service temperature in flexible installation-15 °C to +80 °C

- Temperature during handling, transport and storage+5 °C to +50 °C

- Max. conductor temperature+90 °C

- Max. temperature in short circuit (max. 5 sec)+250 °C

- Test voltage4.000 V AC

- Minimum bend radius in fixed installation7.5 x outer diameter

- Minimum bend radius in flexible installation12 x outer diameter

Other properties

- Standards of referenceUL 1277, UL 1063, NFPA 79 Ed.2007, NEC 336.10 (7), Class 1, Div.2 acc. to NEC Code Art. 336.392.501

- CertificationcUL TC-ER, Ecolab (Resistance against disinfecting and cleaning agents (especially for food & beverage industry)

- Water resistanceAD5 Jets (possibility of water jets from any direction)

- Impact resistanceAG2 Medium (industrial use)

- Oil resistanceUL OIL RES I

- UV resistanceUL 1581 Section 1200

- Chemical resistance in generalPlease refer to technical appendix

- RoHSFree of harmful substances according to RoHS II - Directive 2011/65/EU and Delegated Directive (EU) 2015/863 amending Annex II of Directive 2011/65/EU

- Paint-wetting impairment substances (PWIS)The materials used are free of silicone, cadmium and free of substances that prevent paint from gripping on surfaces

Fire resistant properties

- Flame retardantIEEE UL 1685 UL vertical flame test, CSA FT4

Other colours and configurations possible on request. Sumcab Specialcable Group S.L. (Sumcab) reserves the right to make changes to the product described in this specification without prior notice.While Sumcab makes every reasonable effort to ensure the accuracy of the data at the time of this publication, the information and specifications described in this document are subject to errors or omissions. Sumcab assumes no responsibility that may arise from the use of this specification. Drawings are not to scale unless otherwise specified and are provided for general and informational purposes only. All values represented in this specification should be used only as a guide.

Do you need some help?

Get in touch and we will get back to you as quickly as possible.

+34 93 381 78 76