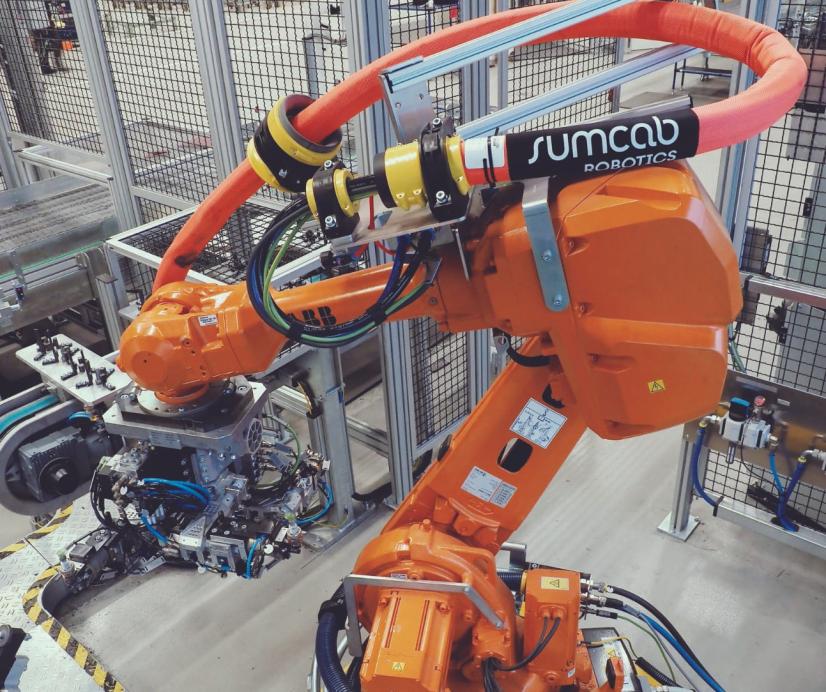

The innovative SUMOTEX energy package system is the result of a creative and efficient partnership and shows that ideas from various partners feed off each other and that trend-setting innovations are created. The fundamental concept and prototype for the new robotic power supply system were developed in collaboration between Mercedes-Benz Group AG and Sumcab, the technological developer of SUMOTEX. After three years of intensive collaboration, the result is a totally disruptive energy package that is remarkably adaptable, reliable and achieves optimal performance in demanding environments. It can outperform even the most conventional energy supply systems.

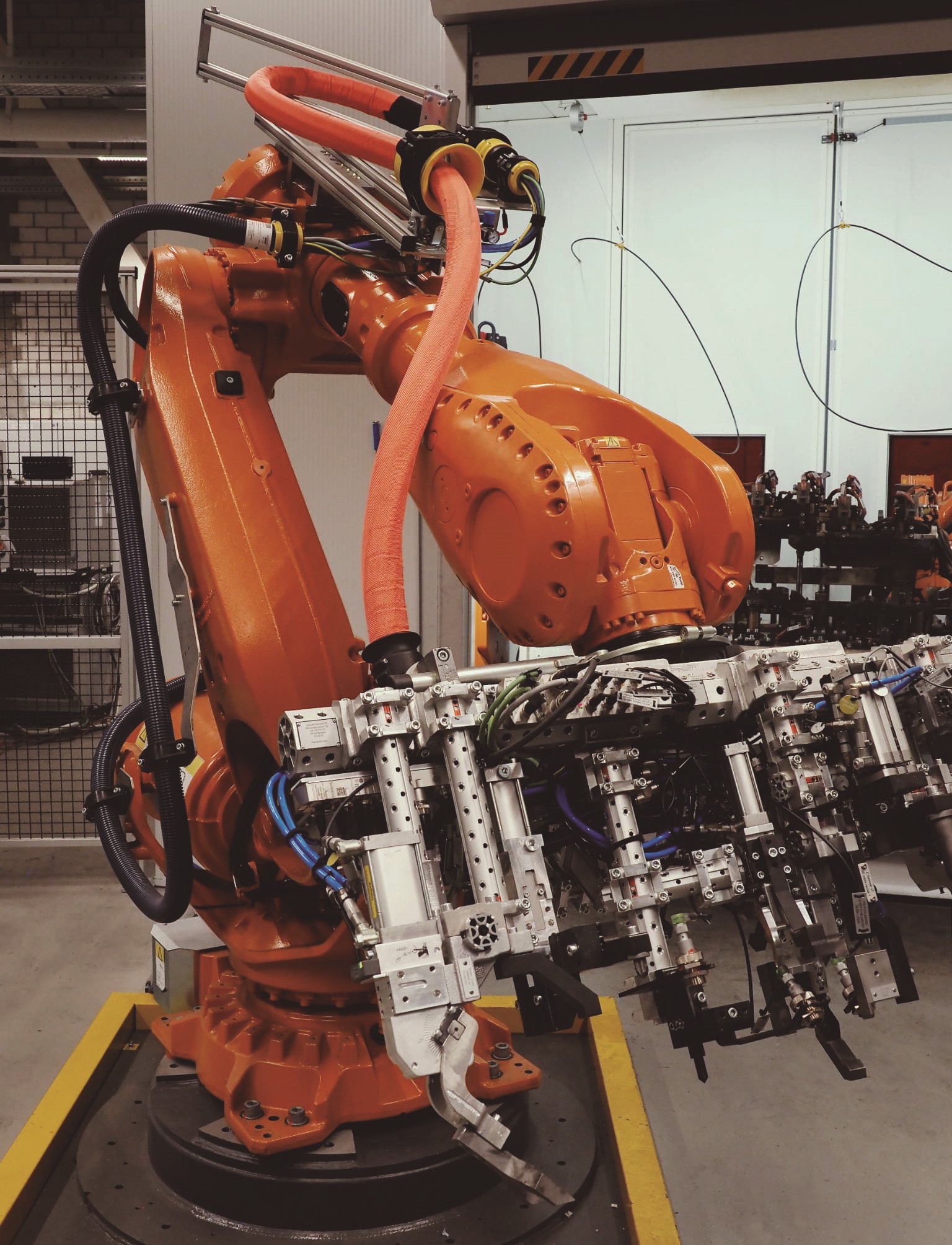

Abrasion on axis t 6 and the dragging of external particles, sagging of corrugated pipes and loud noises when hitting the robot are some of the problems of energy packages in robots. These complications often arise from the use of typical corrugated conduits, which tend to be flimsy and oscillate as they supply cables and tubes along the robot's arms. This results in greater wear, necessitating frequent maintenance or even replacement of the entire energy supply system. Jürgen Ehleiter (1966– 2022), a renowned robotics expert at Mercedes-Benz Group AG, was intimately familiar with these difficulties and dedicated his life work to developing a solution.

From idea to the prototype

Initially, one of Ehleiter’s colleagues had the idea of covering the corrugated tubes with a high-tech fabric to reduce abrasion. However, the fabric did not withstand chafing on the corrugated tube. Finally, Jürgen Ehleiter came up with the solution in his spare time. While cycling he realised that an inflated bicycle tube could bend flexibly and then return to its original shape.

An energy package must seamlessly adapt to the robot arm's movement without sagging and without the need for additional retraction systems or guiding elements. The combination of the two ideas, the air-filled hose and the cover made of high-tech fabric, is the basis of today’s SUMOTEX™. Only through the integration of these elements does the system achieve the flexible rigidity and durability required for the demanding robotic production environment.

Several versions were considered in the design model until Ehleiter successfully demonstrated the basic principle of his vision in a prototype. With this starting point and thanks to teamwork, the effort culminated in the product patent. The innovative nature of the SUMOTEX™ patent idea was also demonstrated in 2020 with the Mercedes-Benz Internal Innovation Award.

Innovation thanks to a successful partnership for the development of SUMOTEX™

In subsequent steps, the company chose to entrust the development to a partner: Sumcab, a manufacturer specialising in high-value-added cabling solutions and services. As a medium-sized company with the ability to make quick decisions and a clear focus on energy supply systems, Sumcab is a company oriented to development engineering with a cross-cutting axis marked by innovation. Its disruptive DNA translates into offering tailor-made, reliable solutions capable of meeting the needs of the market.

For instance, after several attempts, the coating for the new energy package had not yet been resolved. Faced with this challenge, Sumcab revisited the idea and tested it with a seamless circular fabric. The result was successful. SUMOTEX™ now uses a high-performance fabric that can also withstand heavy loads and high pressures in other applications, such as fire hoses.

Thanks to close communication between project partners and the possibility of testing additional developments not only in the “laboratory system” at Sumcab, but also in factory conditions, a rapid evolution towards a mature product was achieved. “Both companies have always worked together,” says Lothar Schütz, CEO of Sumcab Robotics and an expert in the field of robotic power supply systems. “We have repeatedly used feedback from Mercedes-Benz Group AG to improve and further develop SUMOTEX™. For us, this regular exchange was and is extremely valuable.”

For its part, Mercedes-Benz, as partner, likewise benefits from the cooperation: robots that could fail due to high wear and tear on the power supply are quickly equipped with a SUMOTEX™ from Sumcab, showing better conditions regarding service-life. During the collaboration, Sumcab was a key agent in providing solutions both because of the quality of its products and services and because of the professionalism and know-how of its team, always proactive and decisive.

SUMOTEX™ in operation

The new SUMOTEX™ JE line has recently been introduced. Excellence has been achieved based on the original vision and does not require any additional guidance element. Ehleiter himself recognised that his prototype was a long way off achieving the goal and always highlighted Sumcab’s contribution and pioneering work in the project, being particularly pleased that Mercedes-Benz trusted his idea. As a result, SUMOTEX™ is now poised for broader use. The first projects with new robotic systems have already been equipped with SUMOTEX™ and the next step will be to complete the production lines in several plants.

“It is a great honour for Sumcab Robotics to preserve the idea of Mr. Jürgen Ehleiter and keep him in our memory thanks to his invention. Unfortunately, he has left us, now it is up to us to bring this innovative concept of Mercedes-Benz Group AG to maturity”, said Lothar Schütz, CEO of Sumcab Robotics, in December 2022.

SUMOTEX™ has arrived to change everything. With just over a year of life since its launch, many customers are already benefiting from its reliability and adaptability with excellent results in rigorous and unique applications. Thus, the contribution of SUMOTEX™ opens up a very promising future of possibilities in environments as demanding as automation and robotics.