Applications involving continuous movement require special cables with advanced mechanical resistance qualities. In automated and industrial robotics applications, such movement rapidly deteriorates conventional cabling.

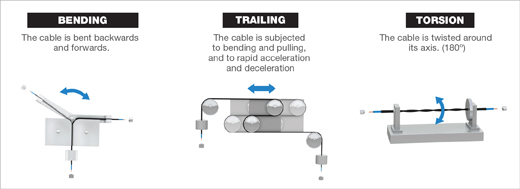

The problem lies in the fact that most cables are not designed for this type of motion (bending, pulling and twisting) and wear quickly. Repeated flexing in copper conductors causes them to “cold harden” and break: cold copper conductor wires are stretched beyond the limits of their elasticity. When a conductor is flexed over a radius that is too small, it becomes overstretched. This action alters the internal structure of the conductor causing it to become brittle, and therefore liable to breakage.

Similarly, the friction created by the internal elements of a cable in motion can generate enough heat to cause the cable insulation, shielding and/or sheath to fail. By internal elements we are referring to the different layers and parts in a cable, such as conductors, insulation, shields, protection tapes, outer sheath, etc.

Sumflex Mechatronic

Guaranteed quality and reliability

Process automation machines are designed to operate at higher speeds than previous generations and are equipped with increasingly complex vision and control systems as well as a wide variety of sensors. This new operational scenario demands more resistant and reliable cables.

At Sumcab Tailor Made Cables we have created the Sumflex Mechatronic cable, compliant with the most stringent requirements for mechanical resistance, chemical aggression and thermal range. It is designed to withstand millions of flexing, torsion and traction cycles over a small bending radius (up to 5 x d). In addition, it is highly resistant to external environmental hazards such as temperature variations, oil/grease and chemicals.

The reliability of our products is ensured at our own technical laboratory equipped with 3D testing system. This system allows cables to be tested under conditions of rapid acceleration and deceleration, traction forces, compression and continuous bending and twisting.

Example of Sumflex Mechatronic cable test

During and after testing (up to 10 million cycles) the cable is monitored for damage or failure in any of its components.

Sumflex Mechatronic

The most advanced solution for industrial automation

Using the right cable impacts directly on automation equipment reliability. Understanding the causes of cable failure in applications of this nature enables us to take the appropriate measures during the design phase to increase the reliability of our clients’ entire production systems.

We manufacture solutions!

Manu Romero

CEO Sumcab Specialcable Group

Files

Download the article

Sumflex-Mechatronic-en.compressed.pdf