The industrial environment is one of the main markets in which we work at Sumcab. This sector includes a wide variety of applications, and therefore, different solutions.

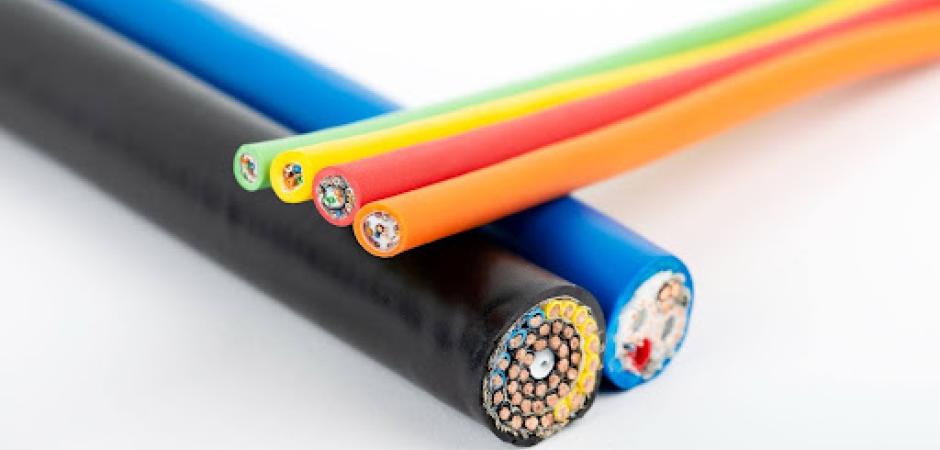

This market’s diversity involves designing specific products appropriate to the characteristics of each installation. At Sumcab we offer a wide range of industrial cables to meet the needs of this sector.

Our company is dedicated to the development and manufacture of cables designed for all industrial sectors. Some of the most important are the following:

- Power generation

- Machines and tools

- Automotive industry

- Packaging

- Food and beverage

- Pharmaceutical

- Chemical

- Wood and pulp

- General manufacturing

- Oil & Gas

- Water treatment

- Mining and minerals

- Metallurgical

- Underwater

- Inspection robots

- Irrigation systems

- Fusion and nuclear

Within each of them there are countless applications for electric cables. That is why we have a wide variety of high, low and medium voltage cable models; cables for cable chains; for industrial robotics; for signal and data transmission; sensors and actuators; communications and telecommunications; for electrical panels in general, etc. You can consult the different categories of applications on our website.

Most common applications of cables in industry

Despite the diversity of markets in which we operate, electrical cables in industrial environments have universal standards across different sectors.

In most projects that we have to tackle, electrical cables have specific functions related to the following areas:

- Industrial automation

- Data and communication

- Instrumentation, control and power

- Various mobile services

- Cable chains

- Articulated robots

The elements that vary the manufacture of one type of electrical cable to another are the application where the cable will be exposed and the conditions that it must withstand.

Types of electrical cables according to their industrial application

Below we review the different electrical cables found in the industry and the primary uses for which they are intended, according to their characteristics.

Sensor cables

These cables usually have three or four cores that make up the whole. The main function of sensor cables is that they transmit signals and data between the sensor itself and the different control units.

Three-core power cables are used for single-phase power supplies and four-core cables for three-phase power supplies.

Armoured cables

Armoured cables are those that have a protective metal sheath and a plastic insulating layer.

The use of this protection system is recommended in industrial installations where mechanical stress could damage the cable, for example in the direct buried, outdoors or in spaces where there may be external agents that could deteriorate the cable.

This variety of cables is the optimal solution in cases where electrical cables have to withstand higher tensile loads.

At Sumcab, within this category, we highlight cables armoured with ATEX steel wire core, capable of facilitating the transmission of signals between equipment in industrial installations carried out in environments with atmospheres at risk of explosion.

Spiral cable

Spiral cables are widely used in the telecommunications sector, although they also have various applications in the medical or aerospace industries.

Its spiral design has the main characteristic of extending its retracted length up to 5 times. Spiral cables are mainly used to connect equipment and machinery with different moving parts, since these cables can be extended.

CY cables

CY cables are used to transmit power without interference. They have a copper wire braid and a PETP separator that protects the cable from mechanical stress or external electromagnetic interference.

SY cables

SY cables are control cables that stand out for their flexibility and are mainly used to connect different equipment. These types of cables are widely used in automation systems.

In addition, SY cables stand out because they offer greater durability and have sufficient protection for very diverse applications, thanks to their galvanised steel wire braiding.

YY cables

Control cables whose main application is the construction, transportation and automation industries.

They do not have the same level of protection as the previous ones, but they are applicable to many environments, as long as the existing mechanical stress is not too high.

Multi-pole industrial cables

Electrical cables have more than one core of cable wires and are used in all types of industrial applications.

They usually have a protective sheath, which they can do without on specific occasions.

Solar cables

Interconnection cables applied in photovoltaic energy installations that is responsible for connecting the solar panels and the rest of the components of the system.

It offers high levels of resistance and durability and has the ability to withstand the most adverse weather conditions, UV rays and a wide range of temperatures.

The insulation applied to solar cables enables them to resist mechanical and thermal loads of different types.

High temperature cables

These cables have been designed with outstanding thermal properties so that they can be used in environments with extreme temperatures.

Their resistance enables them to withstand high temperatures of up to +260ºC and peaks of 350ºC, as well as very low temperatures, down to -90ºC.

These are cables normally used in aeronautics, the naval industry, the metallurgical industry or for the wiring of rotary machines.

Cables for temperature control and regulation

This type of cable is intended for the connection of temperature sensors. It requires having the same alloys as the measurement system to connect the entire system with maximum precision and effectiveness.

They are also called thermocouple cables and each model has a specific combination of metal alloys by which it is possible to distinguish them.

Braided and multi-pair industrial cables

Set of cables formed by two different electrical conductors twisted in the same circuit.

These types of cables are an optimal solution when you want to eliminate electromagnetic interference from external sources.

Types of electrical cables according to their installation

Electrical cables can be made of different materials depending on the application and environment where they are installed.

Based on the purpose for which each type of cable is manufactured, we can make the following distinction between the most used:

- Cables for explosive atmospheres

- Control cables

- Cables for automatic cable retraction systems

- Instrumentation cables

- Cables for industrial communication

- Cables for motors and drives

- Cables for articulated robots

- Festoon cables

- Cables for intrinsic safety circuits

- Data transmission cables

Are you looking for specific electrical cables for the industrial sector? Request your quote and we will offer you customised solutions for any professional work environment.